Industrial Coffee Mill Overview: Increase Performance and Top Quality

In the affordable landscape of coffee manufacturing, choosing the best industrial coffee grinder plays a crucial function in enhancing both effectiveness and product top quality. Recognizing the subtleties of various grinder kinds and essential functions-- such as adjustable grind settings and robust building-- can considerably affect the last taste account of the coffee. The optimization of the grinding procedure, paired with diligent upkeep, is important for sustaining efficiency over time. As we discover these vital components, it becomes noticeable that the ramifications prolong past mere equipment option, impacting general organization success in ways that call for closer exam.

Recognizing Grinder Kinds

When choosing a commercial coffee mill, recognizing the numerous kinds offered is crucial for enhancing both flavor removal and functional performance. The 2 key sorts of mills are blade grinders and burr grinders. Blade grinders utilize sharp blades that chop coffee beans into irregular sizes, resulting in unequal removal and potentially unfavorable tastes. While blade grinders are commonly much more budget-friendly and suitable for small procedures, they are normally not suggested for industrial use.

Eventually, picking the appropriate kind of mill is essential to preserving quality and performance in coffee manufacturing, making it important for services to buy high-grade burr mills for optimal outcomes.

Trick Features to Think About

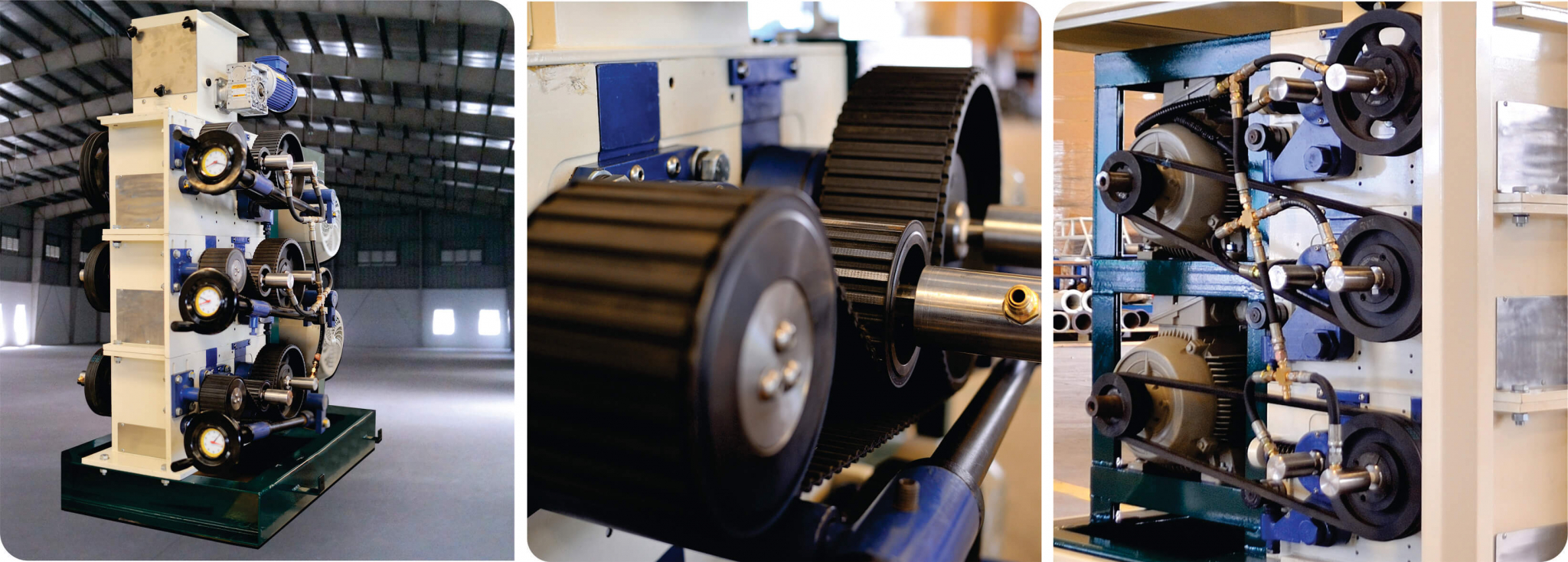

Picking an industrial coffee mill needs cautious consideration of a number of essential attributes that can dramatically affect both performance and the overall coffee experience. Among the primary facets to examine is the grinding mechanism. Burr mills are normally chosen over blade mills, as they provide a constant work dimension, which is important for optimum extraction and flavor.

One more vital feature is the grinder's ability. Depending upon the volume of coffee you need to procedure, select a version that can manage your demands without compromising speed or high quality. Furthermore, consider the work setups supplied. A functional grinder with multiple setups permits you to customize the grind size to different brewing methods, boosting the coffee's taste profile.

Review the grinder's noise degree, especially in an active café or manufacturing atmosphere, where extreme sound can be turbulent. Spending in a grinder that balances these features can significantly improve both operational performance and the top quality of the coffee offered.

Optimizing Grinding Process

To attain the best outcomes in coffee preparation, maximizing the grinding procedure is important. The grind size dramatically affects removal, taste, and general quality of the brewed coffee.

Additionally, checking the grinding speed can optimize the procedure. Slower grinding commonly generates less warmth, maintaining delicate tastes and aromas. Alternatively, faster grinding might produce extreme warm, adversely impacting the coffee's top quality.

Maintenance and Treatment Tips

Proper upkeep and care of industrial coffee mills are vital for making certain ideal efficiency and longevity. Regular cleaning is the foundation of maintenance; residue buildup can impact flavor and grinding efficiency. It is a good idea to cleanse the mill after each use, wiping down the outside and removing any coffee premises from the burrs.

Furthermore, evaluate the grinding burrs for wear and tear. Dull burrs can endanger grind uniformity, so they must be changed as necessary. Industrial Coffee Grinder. Regularly calibrating the mill is likewise essential, as Continue this preserves the preferred grind dimension for various developing methods

Lubrication of moving parts must be executed according to the maker's specifications, as this lowers rubbing and extends the life of the equipment. It is vital to utilize food-grade lubes to make sure safety and security and conformity with health laws.

Lastly, keep the mill in a dry and steady environment to stop corrosion and corrosion. By sticking to these upkeep and care suggestions, operators can boost the efficiency of their industrial coffee grinders while ensuring premium result and prolonged functional life.

Roi Analysis

Evaluating the roi (ROI) for commercial coffee mills is important for companies looking for to enhance their coffee production capacities. A complete ROI analysis helps determine the economic feasibility of spending in premium mills, permitting companies to consider the initial costs against prospective gains.

To carry out a thorough ROI analysis, companies must think about several vital elements. Evaluate the acquisition price of the mill, including installment and any type of essential alterations to existing framework. Next off, calculate operational costs, including power usage, maintenance expenditures, and labor efficiency renovations. High-performance grinders frequently result in decreased grinding time and increased throughput, which can considerably enhance performance.

In addition, take into consideration the influence on item high quality. Industrial Coffee Grinder. Superior grinders generate a more consistent grind size, which can boost flavor profiles and customer fulfillment, ultimately driving sales. By increasing the high quality of the final item, organizations can justify higher pricing, bring about increased earnings

Verdict

In summary, an industrial coffee mill plays a critical duty in enhancing both efficiency link and item high quality within coffee production. By choosing top notch burr grinders outfitted with crucial functions such as flexible grind setups and resilient building and construction, services can ensure optimum taste removal. Normal upkeep is essential for sustaining mill performance and taking full advantage of client contentment. Ultimately, the calculated investment in a reliable grinder adds dramatically to improved income and competition in the coffee industry.

In the competitive landscape of coffee production, selecting the appropriate industrial coffee grinder plays an essential function in boosting both efficiency and product quality. The 2 key kinds of grinders are blade grinders and burr grinders. Within the burr mill classification, there are flat burr grinders and conelike burr mills, each with its benefits. Burr grinders are typically liked over blade mills, as they offer a regular grind size, which is vital for optimum extraction and flavor.

In recap, an industrial coffee mill plays a crucial role in boosting both efficiency and item quality within coffee manufacturing.